Introduction:

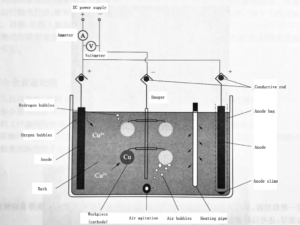

Anode bags play a crucial role in the electroplating process by preventing the formation of fine to finest particles. Among the various challenges faced in electroplating, acid copper plating stands out, and the role of Anode bags becomes even more significant. Puritec Mohali is a company dedicated to providing high-quality Anode bags for a wide range of plating applications. They offer Anode bags tailored to the specific chemical compositions involved.

Enhancing Plating Quality with Anode Bags:

At Puritec, our team is committed to understanding the challenges associated with Anode bags and educating our customers about their usage. For acidic applications, we recommend the use of Anode bags made from Polpropylene (PP) media, as PP has exceptional chemical resistance. Selecting the wrong Anode bag can compromise all the efforts made by the electroplating industry. For alkaline media, Anode bags made from polyester and nylon are recommended.

The Importance of Mesh and Micron Size:

The selection of Anode bag mesh and micron size also plays a vital role in the electroplating process. Our company offers Anode bags ranging from 1 to 50 microns. Some electroplating processes require fast filtration, while others, such as ABS plating, necessitate a slower filtration rate to retain the smallest particles and ensure a clear solution akin to pure water.

Puritec Mohali: Leading the Industry:

In the realm of Anode bags for automobiles, Puritec Mohali enjoys a leadership position. We are grateful to the industry leaders who have given us the opportunity to showcase our capabilities and contribute to improving the quality of electroplating.

Conclusion:

Anode bags serve a critical function in electroplating by preventing the development of fine particles. Puritec Mohali stands out as a dedicated company, focused on providing Anode bags tailored to specific plating applications. By understanding the challenges and requirements of the electroplating industry, Puritec offers solutions that enhance the quality of plating processes. With their leadership in the automobile sector, Puritec is committed to contributing to the advancement of electroplating quality.